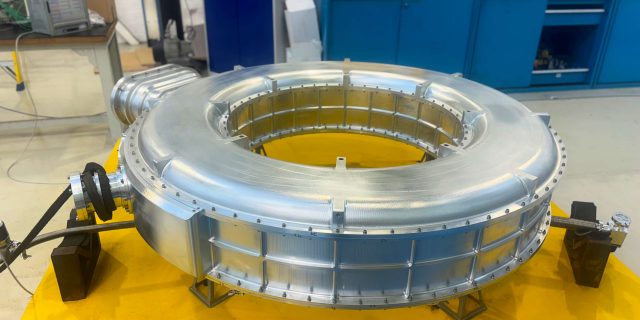

BEL Engineering has manufactured three welded bespoke assemblies to support a major submarine project in Australia.

The assemblies, which have been manufactured as part of fleet upgrade, will be used to support specialist sonar equipment carried on submarines at sea.

The components were manufactured using the Skoda HCW2 floor boring mill machine at the BEL Engineering site in Cramlington, Newcastle upon Tyne. Manufacturing engineers had to take extra precaution to ensure the assemblies did not disrupt the equipment’s sensors as failure to do so would fail the project.

Once complete, the assemblies underwent load testing to ensure the components could withstand the weight of the equipment. The assemblies were then painted and shipped to the customer within a 16 week lead time.

The client representative, said: “The collaborative approach by the teams at BEL Engineering helped us overcome the problems we had along the way. We were impressed with the success of the project and we look forward to working together again.”

David Sidebotham, Business Development Manager at BEL Engineering, said: “This was a challenging project due to the nature of the scope. Meeting regularly with the client and all stakeholders for project updates helped the project flow.

“The BEL Engineering team really came together to make this work and because of this, we have secured further contracts. Great work from everyone involved.”

Find out more about our manufacturing capability within the defence industry.