News

News

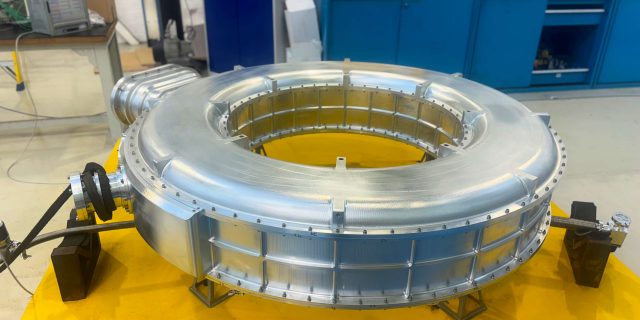

Assembly and Test

We can design bespoke testing plans to suit our customers’ criteria, including factory acceptance (FAT), pressure, hyperbaric, cryogenic, electrical, load, and functional testing.

Our dedicated facility allows for products up to 50 tonnes to be fully assembled complete with an integration and non-destructive testing area. In addition, BEL Engineering also benefits from the world class testing resource of the British Engines Group, with access to the numerous testing chambers available at Tyne Pressure Testing. Tyne Pressure Testing is a multi-million pound testing facility based in the North East of England, offering a variety of pressure testing services. The facility operates nine hyperbaric testing chambers, including one of the largest commercially available chambers in the world, as well as two environmental test bays and one conventional pressure testing bay.

Members of